5 Less-Known Drill Press Attachments (Other than Drilling)

The drill press is arguably the workshop’s most important tool. They’re versatile, dependable, accurate and useful in too many ways to count. They’re the perfect addition to any workspace, whether you’re a regular craftsman or an occasional hobbyist.

But did you know it’s capable of doing more than drilling and boring? With a few attachments and some creativity, you can turn your drill press into a sander, buffer, grinder, cleaner and more. These interchangeable attachments will enable greater versatility in even the smallest workshop, and you’ll save on space and specialty tools in the future.

All of the attachments below are easily affixed to your drill press thanks to the mounted 1/4 inch shank already built into the attachment. All you have to do is install it as you would any drill bit and you’re good to go.

Sanding Drum and Sleeves

Sanding Drums and Sleeves are some of the most useful attachments available for your drill press. They are ideal for smoothing out rough edges and cuts, sanding inner surfaces of shallow or deep drilled holes. They are also useful for cleaning up band-saw marks on contour cuts and other scuffs or imperfections.

There are many DIY versions of this system where you can make your own out of a wooden cylinder with an embedded bolt as a shank and a groove to hold the sanding paper with glue. Alternatively you can buy a kit that's ready to go in order to save time and frustration.

This system is unique in that it relies on rubber expansion due to the “squeeze” pressure from the two washers and the nut, it helps to insure to keep the sanding sleeve in place.

Sanding drums and sleeves can come in variable diameters and lengths and fit into large or deep holes, allowing you to sand round, curved or contoured sections of your work-piece with ease and accuracy.

Molding Flap Sanding Wheels

A reliable flap sanding wheel is a game-changer for your home workshop. Through our experience a 4 inch diameter wheel can provide incredible flexibility and versatility for sanding and finishing a variety of surfaces including: Wood moldings and panels, Contoured or profiled surfaces or textured work pieces like carvings, and turnings.

A sanding wheel kit for your drill press can eliminate the need for hand-sanding, especially in those detailed areas where extreme precision is necessary, if you were to use any other means for finishing.

It’s basically a flexible cloth-backed sanding flaps that will conform to the shape of your work-piece, this attachment is mounted on a 1/4 inch shank that universally fits onto any drill chuck.

Wire Brush Attachments

Wire brushes are available in an array of shapes and diameters, when they are mounted on a 1/4 inch shank they can fit easily on any drill press or even a regular drill for portability.

They are ideal for removing rust, stripping paint, glue or gunk. They can also be used to blend edges, deburr sharpened edges and more. Though these brushes can be too rough for aluminum and soft metals, they will perform admirably on steel or other hard metals without harming them.

The drill press wire brush attachment can make removing rust, paint, and other materials incredibly easy, reducing your task time by as much as 50% in comparison to doing it by hands.

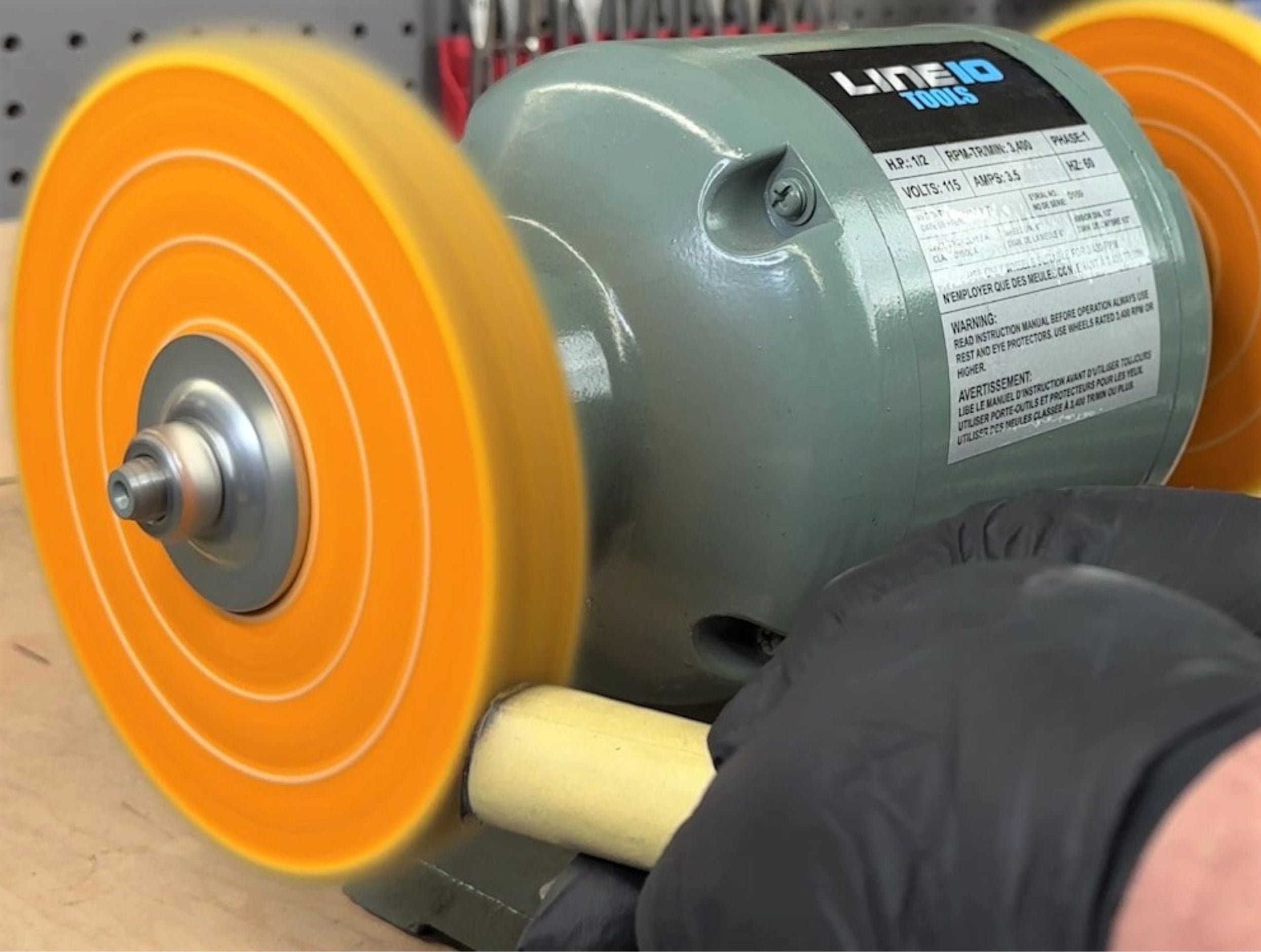

Drill Arbor Adapter for Buffing and Grinding Wheels

Have you ever thought you can use your drill press as a grinder or buffer?

A 1/2 inch arbor adapter will allow you to do just that, since you can mount any disc with a 1/2 inch arbor hole, allowing you to use your drill as a grinder or buffer in a pinch! especially if you want a slower cooler operation than a bench grinder.

Thanks to the 1/4 inch shank on the opposite side it will fit right into any drill easily.

The threads are left-handed to keep it tight and secure. It should also have two extra wide washers to sandwich the wheels from both sides, thereby providing increased strength and stability, so your discs won’t be flying around in your workshop anytime soon.

Buffing Attachments

1/4 inch mounted buffing attachments can turn your drill press into a polishing and buffing machine. This combination makes for an easy one handed operation and solution for polishing or buffing hard metals.

It can be ideal for removing sharpened edges, erasing scratches, and for heavy-duty cleaning purposes.

Final Thoughts

Hopefully you can see your drill press in a different light, or perhaps this article will convince you to buy one if you don’t already have one. I guarantee you that it will be one of the best tools in your shop, it can be a multipurpose workhorse of a machine if used right, Your Drill Press Can Work Harder So YOU

Don’t Have To..

Leave a comment