Got a Drill? Here are 3 Sanding Attachments for Drills That Will Save Your Time and Money

Whether at home or in the workshop, a power drill is likely the first tool you think of when getting work done as it's convenient, portable, and Versatile.

If you ever need to sand and finish your workpiece, sometimes you don't have to buy a dedicated sanding machine or waste hours sanding by hand. Given the proper attachment, a drill can be your most handy ally for all things sanding.

Here are three sanding attachments for drills to get your work done in no time.

Sanding Attachment # 1: Sanding Drums and Sleeves

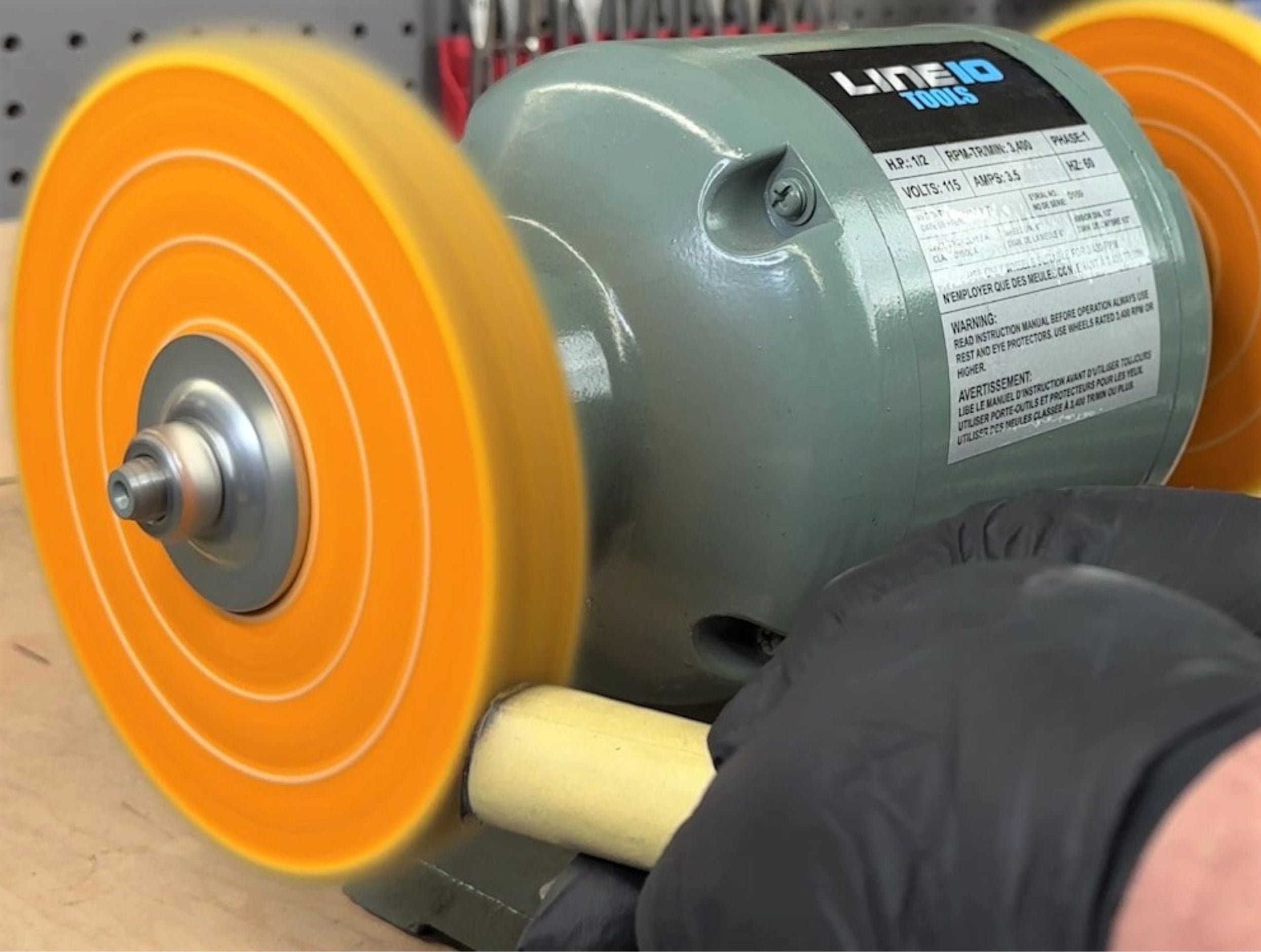

Attach sanding drums and sleeves on your drill. Why sand by hand or buy a spindle sander machine?

Sanding drums and sleeves are great for smoothing out round edges, contours, and concaves as it sands through rotation action. All you need is sanding sleeves with a good assortment of grits and a shank-mounted rubber drum to get any round sanding job done quickly and precisely.

Did you know these could be attached to more than just a spindle sander?

Sanding drums could be attached to a drill by the shank. A 1/4-inch shank is universally compatible with any drill. Using a drill will not only save you money on purchasing a dedicated machine, but it will also allow you to sand your work in hard-to-reach angles, especially if the job area is tight.

Some examples of sanding jobs with a drill drum sander include:

- Sanding the inside edges of a hole

- Sanding the rounded side of a large table

- Getting tool marks off an antique tool

- Removing rust off a piece of metal

Get your hands on some sanding drums and sleeves for your drill

Sanding Attachment # 2: Flap Sanding Wheels for Drill

Get Your Sanding Done INSIDE and OUT with a Flap Sanding Wheel

Like the sanding drums, a flap sanding wheel is excellent for getting round edges and concaves, thanks to its rounded surface. The most significant difference is the flaps; they offer flexibility conforming to the shape of the surface you are sanding. Using the flap sanding wheel, you will not have to worry about damaging your work with the softer and more flexible flaps. The size and shape of the wheel allow you to have a more controlled way to sand a specific small surface as you are bound to sanding at the length of a sanding drum. Like the sanding drums, these flaps allow you to sand at specific angles using a drill that you wouldn't be able to do if you had a massive machine.

Some examples of sanding with a flap sanding wheel on a drill include:

- Removing wooden burrs after shaping and cutting

- Breaking sharp edges

- Smoothing out precise areas of a surface

- Sanding the inside edges of a hole

Get Your Hands on Sanding Flap Wheels Today

Sanding Attachment # 3: Molding Flap Sanding Wheels for Drill

Does Hand Sanding Gets on Your Nerves? Check Out the Molding Flap Sanding Wheels for Drills

The molding flap sanding wheel takes a regular flap sanding wheel to the next level when it comes to preserving your work. The flaps are larger and more flexible, it conforms to the shape of the workpiece. It's great for preserving details; you won't have to worry about altering the shape of the surface, especially when you are engraving; the molding flap sander is flexible enough to maintain and clean up fine engravings and details.

Usually, the molding flap sander is used during the finishing process of your sanding job. This drill attachment is the perfect substitution for sanding by hand, where it can take you hours to finish. Using a 1/4 inch shank, you can take it to the next level by attaching it to your drill and sand your work at the angles you need and save a lot of time.

Some examples of sanding jobs for using molding sanding flap wheel with a drill include:

- Finishing textured wood pieces

- Sanding round and irregular turnings and carvings

- Finishing irregular wood moldings

- Getting your raised panels sanded and finished.

Finish your Work with the Molding Flap Sanding Wheels for Drills

Final Thoughts: Why Not Just Use a Dedicated Sanding Machine?

Albeit nothing can substitute the effectiveness of a professional-grade spindle sander or a belt sander. Sometimes you don't have the storage space, frequent need, or the budget to get a heavy piece of machinery for a lot of money, especially when you are not going to use it all the time.

There are also cases where using a drill has its advantages over large sanding machines. Firstly, sometimes it makes sense to apply your drill to the surface or object rather than the opposite (using a large spindle sander is not exactly convenient to sand the round legs of a heavy table). Depending on the size of your work, it may be too challenging to get certain areas of a larger piece of work sanded with a large machine.

It's easier to use a lightweight tool on a large object or surface. Furthermore, many argue that a drill-press may not be as stable or stationary as a spindle sander and can ruin your work if you are not skilled or careful.

As stated, for regular and intense smoothing for surfaces, it's challenging to replicate the effectiveness of spindle and belt sanders. However, sometimes the drill is your best option, especially for those who require a quick and precise sanding job.

In conclusion, the next time you decide to get your sanding work done, you don't need to go out and buy a dedicated sander. Sometimes, a drill is just the power tool that you need.

I recently did some fiberglass repair in my car. What do you recommend, a cordless orbital sander or a cordless drill with attachments.

Thank you

Leave a comment